Raw materials, will recycling save the EU from dependence on China? CDP report

Recycling and the circular economy can mitigate the risks of sourcing critical raw materials from abroad. What the CDP report says

Increasing the resilience of the EU and ensuring a secure and sustainable supply requires considering risk mitigation strategies along the supply chains .

The circular economy can make an important contribution to mitigating the mismatch between supply and demand. For example, by 2040, through the recycling of used batteries, Europe could meet more than half of the demand for lithium (52%) and cobalt (58%) activated by electric mobility.

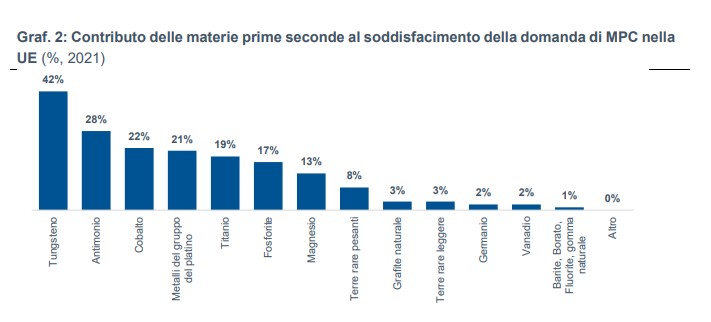

The EU already resorts to the use of secondary raw materials deriving from recycling:

- for some raw materials, such as tungsten and platinum group metals, recycling is already able to satisfy between 20% and 40% of demand;

- in the case of other raw materials, especially used in renewable energy technologies or in high-tech applications, such as rare earths, gallium or lithium, secondary production provides a marginal or no contribution.

THE URBAN MINES

To enhance the production of secondary raw materials, it is necessary to exploit "urban mines", i.e. enhance the collection, recovery and recycling of technological products, such as waste electrical and electronic equipment (WEEE) and batteries/accumulators.

One of the main advantages of urban mines is their wide availability: the quantity of decommissioned electrical and electronic equipment is in fact growing (+2 million tons per year globally13) also due to increasingly reduced times of technical obsolescence, especially for cell phones and computers.

Furthermore, a considerable variety of MPCs can be recovered from technology products. Suffice it to say that a smartphone contains more than 30 natural elements, of which at least half are critical.

EUROPEAN WEAKNESSES ON THE RECYCLING OF CRITICAL RAW MATERIALS

Although already underway in Europe, the recovery of these materials on an industrial scale has weaknesses in terms of:

- economic feasibility and high costs of plants for the recovery of some materials such as lithium and rare earths;

- imperfect collection systems that prevent MPCs from reaching the treatment site;

- an increasing complexity of the products to be recycled, due to the miniaturization and mixing of materials which lead to a greater complexity of recycling;

- improper handling of e-waste, for example through informal recycling operations, leading to material losses;

- the export of waste to which the risk is connected that the same will not be recycled or will be recycled in a less efficient way.

THE ITALIAN POTENTIAL ON RECYCLING

In Italy, the potential deriving from the recycling of technological products is high: if the collection rate of the best European performers (70-75%) is achieved, around 7.6 thousand tonnes of MPC could be recovered, equal to 11% of imports from China in 2021.

However, some critical issues do not allow you to fully exploit this potential. Among them:

- a collection rate lower than the European average both for WEEE (39.4% vs 46.8%) and for batteries and accumulators (43.9% vs 51.3%)17;

- the scarce development of a complex technology plant network for the recovery of MPC. There are still few companies that have the ability to complete the recycling of critical raw materials: the processing stops in an intermediate phase, i.e. the shredding which is only the preparation for recycling.

MINING WASTE

Like technological products, extractive waste could also be an alternative source for the recovery of secondary raw materials. Italy has large quantities of extractive waste stored in storage facilities where MPCs are available.

Despite the advancement of knowledge on mining residues, to date the information regarding their mineralogical and chemical composition, physical properties and their location are still partial and not very homogeneous.

However, recovery from extractive waste is considered less efficient than from technological products because in the former:

- it is possible to recover only a few raw materials, unlike technological products;

- raw material concentrations are up to 1,000 times lower22

Circularity is therefore a central element of the European strategy for the mitigation of supply risk. However, increasing the collection rate is not in itself sufficient to ensure autonomy.

This is a machine translation from Italian language of a post published on Start Magazine at the URL https://www.startmag.it/energia/riciclo-materie-prime-critiche-cdp/ on Fri, 02 Jun 2023 05:24:05 +0000.