An innovation makes the cost of biofuels finally competitive

A new study from the University of California – Riverside (UCR) has found that introducing a simple renewable chemical at the pretreatment stage can finally make the production of next-generation biofuels cost-effective and carbon-neutral. carbon. The first step, breaking down plant matter, has always been the most difficult when it comes to producing fuel from plants.

For biofuels to compete with oil, biorefining operations must be designed to better utilize lignin. Lignin is one of the main components of plant cell walls. It provides plants with greater structural integrity and resistance to microbial attacks. However, these natural properties of lignin make it difficult to extract and use from plant matter, also known as biomass.

UC Riverside research associate professor Charles Cai invented CELF, which stands for Co-solvent Enhanced Lignocellulosic Fractionation. This is an innovative biomass pretreatment technology that will allow the lignin bonds to be dissolved, making it treatable in the biofuel production process.

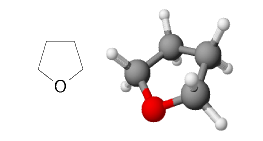

“CELF uses tetrahydrofuran or THF to supplement water and dilute acid during biomass pretreatment. It improves overall efficiency and adds lignin extraction capacity,” Cai said. “And best of all, THF can be made from biomass sugars.”

An important Energy & Environmental Science paper details the extent to which a biorefinery using CELF offers economic and environmental advantages over petroleum fuels and previous biofuel production methods.

The paper is a collaboration between Cai's research team at UCR, the Center for Bioenergy Innovation operated by Oak Ridge National Laboratories, and the National Renewable Energy Laboratory, with funding from the U.S. Department of Energy's Office of Science . In this study, the researchers consider two main variables: what type of biomass is most ideal and what to do with the lignin once it is extracted.

First-generation biofuel operations use food crops such as corn, soybeans and sugarcane as feedstocks, or feedstocks. Because these feedstocks divert land and water from food production, their use for biofuels is not ideal.

Second generation operations use non-edible plant biomass as feedstock. An example of biomass feedstocks are wood residues from milling operations, sugar cane bagasse or corn stubble, all of which are abundant and low-cost by-products of forestry and agricultural activities.

According to the Department of Energy, in the United States alone, up to one billion tons of biomass could be made available per year for the production of biofuels and bioproducts, capable of replacing 30% of our oil consumption and creating new jobs nationwide.

Because a CELF biorefinery can more fully utilize plant matter than previous second-generation methods, the researchers found that a heavier, denser feedstock such as hardwood poplar is preferable to less dense corn stubble. of carbon, to obtain greater economic and environmental benefits.

Using poplar in a CELF biorefinery, researchers demonstrate that sustainable aviation fuel could be produced at a breakeven price of $3.15 per gallon of gasoline equivalent. The current average cost of a gallon of jet fuel in the United States is $5.96. This would make biofuel even cheaper than current aviation fuels.

The U.S. government issues credits for biofuel production in the form of Renewable ID Credits, a subsidy intended to support domestic biofuel production. The level of these credits issued for second-generation biofuels, the D3 level, typically trades at $1 per gallon or more. At this price per credit, the paper shows that you can expect a rate of return of more than 20% on the deal.

“Spending a little more on a more carbon-rich feedstock like poplar still produces more economic benefits than a cheaper feedstock like corn stubble, because you can get more fuel and chemicals out of it,” Cai said .

The paper also illustrates how the use of lignin can positively contribute to the overall economics of the biorefinery, keeping the carbon footprint as low as possible. In older biorefinery models, where biomass is cooked in water and acid, lignin is mostly unusable beyond its calorific value.

“Old models chose to burn lignin to supplement the heat and power of these biorefineries because they could only exploit biomass sugars—an expensive proposition that left a lot of value off the table,” Cai said.

In addition to better use of lignin, the CELF biorefinery model also proposes to produce renewable chemicals. These chemicals could be used as building blocks for bioplastics and flavoring compounds for food and beverages. These chemicals absorb some of the carbon present in plant biomass that would not be released into the atmosphere in the form of CO2.

“The addition of THF helps reduce the energy cost of pretreatment and isolates the lignin, so you no longer have to burn it. Furthermore, we can produce renewable chemicals that help us reach near-zero global warming potential,” Cai said. “I think this shifts the needle from second-generation to second-generation biofuels.”

Thanks to the team's recent successes, the Department of Energy's Office of Bioenergy Technology awarded researchers a $2 million grant to build a small-scale CELF pilot plant at UCR. Cai hopes the pilot plant demonstration will lead to large-scale investment in the technology, as harnessing fossil fuel energy contributes to global warming and harms the planet.

“I started this work more than ten years ago because I wanted to make an impact. I wanted to find a viable alternative to fossil fuels, and my colleagues and I succeeded,” Cai said. “Using CELF, we have demonstrated that it is possible to create cost-effective fuels from biomass and lignin and help reduce our contribution to carbon emissions into the atmosphere.”

Therefore, a new production and economic perspective opens up for biofuels which, above all, is finally economically tolerable and no longer a sort of threat to the possibility of providing services to ordinary people.

Thanks to our Telegram channel you can stay updated on the publication of new Economic Scenarios articles.

The article An innovation makes the cost of biofuels finally competitive comes from Economic Scenarios .

This is a machine translation of a post published on Scenari Economici at the URL https://scenarieconomici.it/una-innovazione-rende-il-costo-dei-biocarburanti-finalmente-competitivo/ on Mon, 04 Mar 2024 06:15:48 +0000.