Electric cars, what Italy can do on battery recycling. Reports

A new sector has opened up in Europe that is worth up to over 6 billion euros, in which Italian industry can play a leading role: the recycling of electric vehicle batteries All the data in the study by Motus-E, Strategy& and the Milan Polytechnic

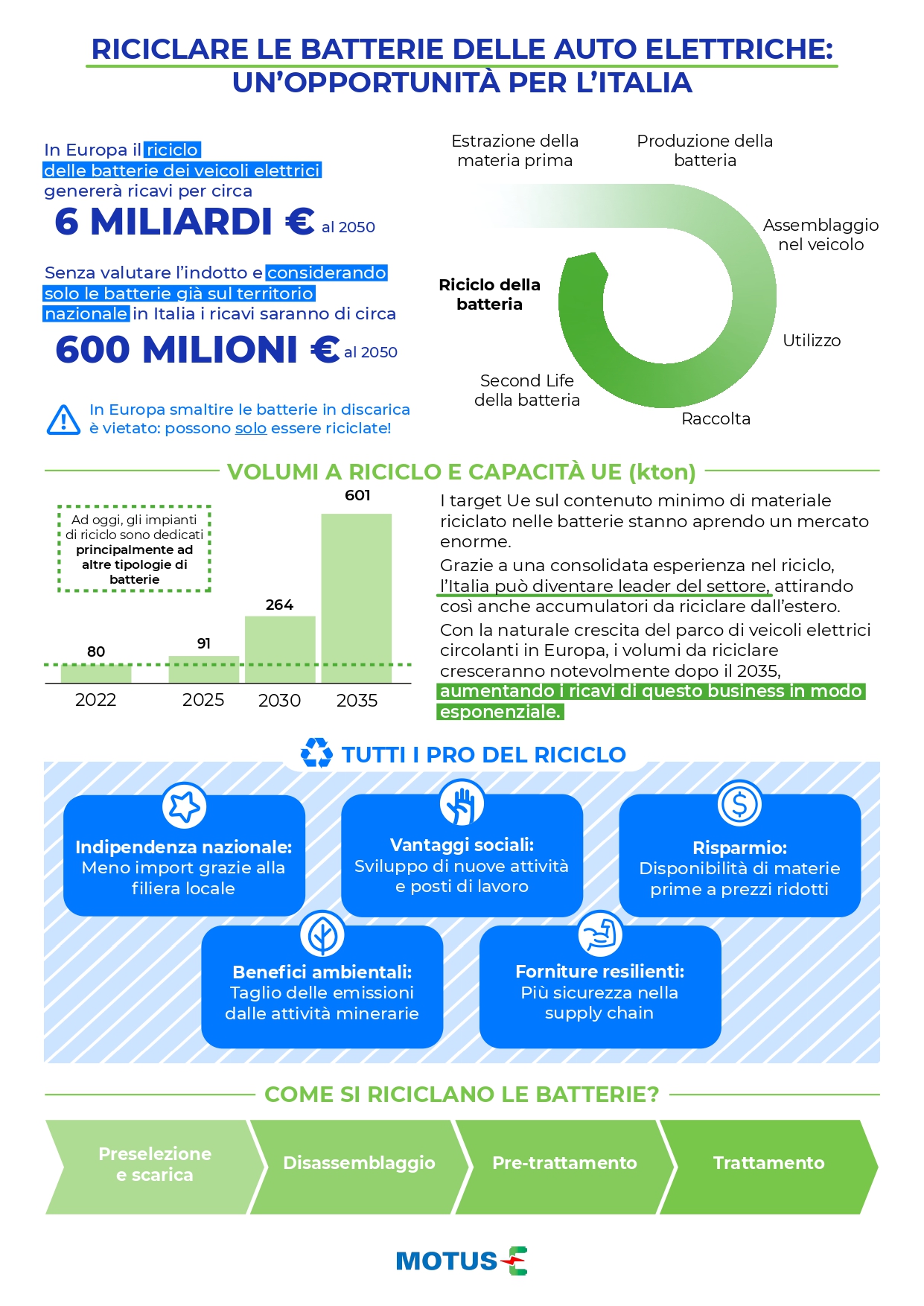

Electric vehicle batteries can only have one destination after use: recycling . Directive 2006/66/EC provides for it, which makes electric mobility a clear example of circular economy. After being used on board cars, vans or other vehicles, the accumulators are first called upon for a second life for public or private stationary applications – in support of electricity grids and renewable sources – to then be sent for recycling to recover all the precious materials that compose them. A business with great development prospects, in which Italy can play a leading role.

THE MOTUS-E STUDY

This is what emerges from the study The recycling of electric vehicle batteries @ 2050: evolutionary scenarios and enabling technologies ”, presented in Milan by Motus-E , Strategy& and the Milan Polytechnic, which by 2050 estimates up to just over 6 billion euros revenues generated in Europe from the sale of recycled nickel, cobalt and lithium.

WHAT ITALY (AND EUROPE) CAN DO ABOUT BATTERY RECYCLING

It is here that Italy can enter to give life to a new industrial chain, strengthened by a recognized transversal experience in recycling.

Considering only the batteries of electric cars that will already be found on the national territory, and without counting all related industries in the sector, the revenues of this activity will amount to between 400 and 600 million euros in the Peninsula, with a dizzying prospect of an increase in natural growth of the electric fleet in circulation, until it stabilizes at regimen on exponentially higher values when all the fleet will be battery-powered. And that's not all – explains Motus-E – because the turnover can expand further, and faster, also by importing accumulators to be recycled from abroad.

Thanks to the new EU targets on the minimum recycled content in electric vehicle batteries, by 2050 the analysis estimates around 3.4 million tons of end-of-life batteries ready to be recycled in Europe, compared to a recycling capacity which today does not exceed 80,000 tons/year. The space for making industry and creating new jobs is therefore enormous.

ALL THE ADVANTAGES OF RECYCLING BATTERIES

According to the study conducted by Motus-E, Strategy& and the Milan Polytechnic, in addition to giving life to a completely new articulated supply chain, with all the associated economic, employment and environmental benefits, recycling these batteries also means making yourself more independent on the extraction and processing of the related raw materials, being able to leverage resources present "in house" and already refined, ready to be reintroduced into the production process.

The battery value chain today is structured in two macro-phases: production and use, and end-of-life management, with the latter including the phases of collection, transport, second life of the battery and recycling, before reaching sale of recycled material. The opportunities deriving from the management of end-of-life batteries – underlines the study – are already beginning to incentivize traditional players in the value chain to extend their skills in roles adjacent to those already covered. Anticipating your moves can trigger a significant competitive advantage.

Finally, the analysis presented today by Motus-E, Strategy& and the Milan Polytechnic is not limited to exploring the economic implications of the recycling of electric vehicle batteries, but also provides a detailed overview of the technology and processes adopted, illustrating the characteristics of the various treatments and anticipating the peculiarities of the next generations of accumulators. From the development of designs that will facilitate recycling to the evolution of the cathode towards a progressive reduction of the cobalt, passing through the replacement of the graphite inside the anode and the transition of the electrolyte from the liquid to the solid state.

EXPERT COMMENTS

"The results of this study are an example of the approach that as a country we must have towards the transition to electric power", explains the general secretary of Motus-E, Francesco Naso, during the presentation of the study, "the engineering skills of the Italy are recognized all over the world, with the right industrial policies we can put them to good use and become leaders in many areas of electric mobility, such as battery recycling. These are opportunities to relaunch the economy and employment that we cannot give to other countries, but we must be quick if we want to seize and exploit them fully".

"The creation of a circular value chain for batteries is essential to exploit the value stored in their residual capacity and in the components that make them up", underlines Massimo Leonardo, Principal Strategy&, "in addition to sustainability, the interest of the actors involved with respect this theme is encouraged by the synergies present between the production and use activities and end-of-life management. Combining the production of batteries with the recycling of waste allows Italian and European producers to reuse the secondary raw material derived from their own waste, and meet the requirements imposed by European regulations. Similarly, automakers can identify the optimal solutions to breathe new life into batteries of which they know their design and characteristics, and leverage their dealer networks for collection. Players able to exploit these synergies right away will enjoy a strong competitive advantage”.

“The technological solutions for the recycling of strategic materials from Li-ion batteries covered in the report, implemented at different levels of industrial maturity, highlight the current recycling capabilities in Europe and the enormous opportunities that this circular business strategy offers to the ecosystem nationwide", concludes Marcello Colledani, associate professor at the Department of Mechanics of the Milan Polytechnic, "the challenges for the future will concern the development of sustainable solutions with high added value to support the supply of high quality raw-secondary materials for the reused in Gigafactories for the production of batteries, currently under development in Europe”.

This is a machine translation from Italian language of a post published on Start Magazine at the URL https://www.startmag.it/smartcity/riciclo-batterie-auto-elettriche-italia/ on Sat, 04 Mar 2023 08:27:28 +0000.