What do we know about the gigafactory that Italvolt wants in Piedmont

The government crisis has impacted the timing of the roadmap that should lead to the opening of the first Italvolt EV car battery plant in Italy, but the gigafactory works continue

If things were already going for a long time, the summer political crisis seems to be the last obstacle on the road that should lead the company of Lars Calstrom , the Swedish entrepreneur behind Britishvolt, in the Bel Paese, to be precise in Piedmont. As reported by the news agency Energia Oltre , it is the CEO who intends to land in Italy, opening a factory in Scaramagno, on the outskirts of Ivrea, to admit the slowdown: “We have some problems with the government crisis. So far we have had the support of the current government, but now we have to wait for the new executive ”.

ITALY LAST FOR GIGAFACTORY?

This is a not insignificant problem given that, as we have seen , in the last period the European states (in particular Spain and France) have been investing a large part of the resources of their respective PNRRs to court international actors who open local own gigafactories, essential to be prepared for the turning point of the farewell to endothermic engines in favor of greener ones, such as electricity and hydrogen. An appointment that Italy, with a few gigafactories scheduled and without a precise industrial plan, is in danger of missing. Tax agreements aside, at least for Italvolt there should be no hitches with the chosen lot: an area, once owned by Olivetti, now abandoned, just outside Ivrea: "it is easier to obtain permits – explained the CEO of Britishvolt – adding that the agreement reached will allow them to "demolish 95% of the buildings" while they will be "saved two for the canteen and a small museum".

WHY DID ITALVOLT CHOOSE SCARAMAGNO FOR THE GIGAFACTORY?

“It is no coincidence that the Italvolt Gigafactory is located in Scarmagno, in Piedmont”, they explain from the Group, perhaps taking things for granted (in reality, as we will see, the situation is a bit more complex). "In the country where Alessandro Volta invented the battery back in the 1800s, we have chosen a site previously used by Olivetti for the manufacture of high-tech products". This is the romantic explanation, it follows the pragmatic one: “It is an area with a rich industrial heritage, especially as a hub of the European automotive industry, and offers a large skilled workforce. It is also a strategic crossroads of the pan-European corridors from east to west and north to south. " In fact, Italvolt holds a purchase option of the Ex Olivetti area.

Speaking with eeNews Europe , Calstrom announced that Italvolt's Gigafactory will produce lithium-ion batteries with MNC technology (nickel, manganese, cobalt) and silicon anodes. However, the CEO admitted that the company is also considering the possibility of assembling solid-state cells. Gigafactory will have internal lines to guarantee the entire accumulator production chain, including not only the processing of materials and components, but also the processing of lithium. In total there will be eight production lines, each with a capacity of around 6 GWh, to power, at least when fully operational, over half a million electric cars.

THE OCCUPATIONAL PLAN

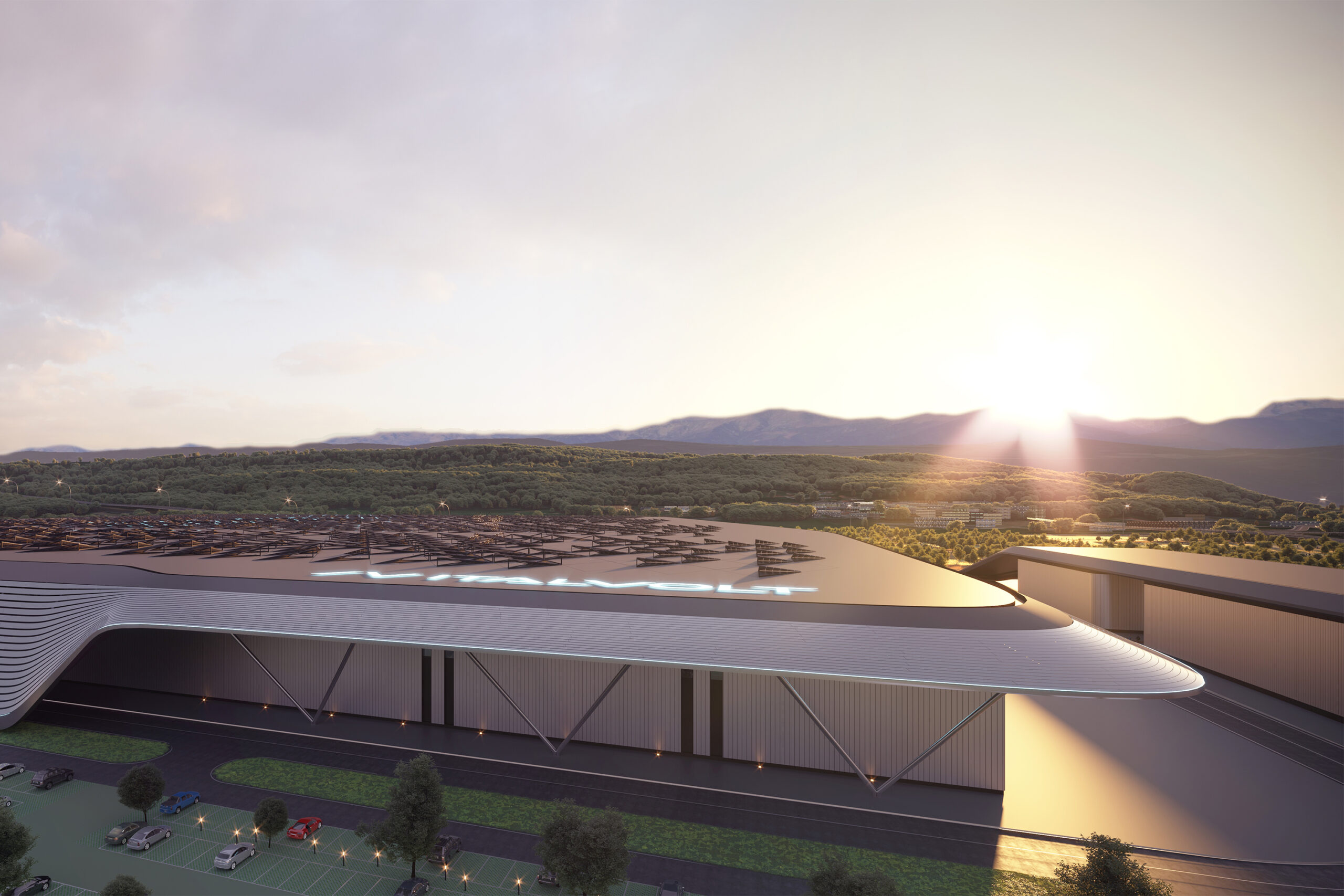

The gigafactory that Italvolt intends to build, with opening scheduled for 2025, consists of a plant designed by Pininfarina with an extension of 300,000 square meters, which in the projects will employ approximately 3,000 people and will reach a production capacity of up to 45 GWh when fully operational. per year, making it one of the largest factories of its kind in the world. “We will not make battery packs yet, we are focusing only on the cells – the CEO revealed. The battery is the platform of the car and must be designed by the car manufacturer. For all this to happen there must be a collaboration between the cell manufacturer, the car manufacturers and the supply chain ”.

The induced should employ, for various reasons, ten thousand units. Naturally the foreign producer insists particularly on this point, in the hope of being able to wrest the best deal from the next government. Still in the last interview released, the CEO stressed how "the transition from the internal combustion engine to electric vehicles will cause unemployment since Italy is strong in endothermic engines and companies will lay off many people". "This – he added – is an advantage for us as it gives us access to a qualified workforce".

THE PARTNERSHIP WITH POLIMI

In the middle of summer, a partnership was signed with the Politecnico di Milano “to create a closed-cycle circular economy for the development of batteries for electric mobility”. As part of the partnership, the recently established interdepartmental laboratory of the Politecnico, CIRC-eV, Circular Factory for the Electrified Vehicles of the Future, will identify primary sources of raw materials and analyze the possibilities of recovering key materials from secondary sources. recycled, such as exhausted batteries.

Within the partnership, the Politecnico di Milano will map the supply chains to help Italvolt find raw materials from primary sources for the construction of the Scarmagno gigafactory, with a fully operational production capacity of 45 GWh. The University will evaluate the quality of materials from primary suppliers to ensure the production of lithium-ion batteries of the highest quality and sustainability. In addition to the primary supply sources, the Politecnico will analyze the flows related to production waste to feed the supply also through secondary sources. The University will evaluate the entire production chain to allow Italvolt to recover key material present in exhausted batteries.

“This analysis – explain the parties – will be essential to minimize waste and develop a fully efficient production process. Recycling of battery components will play an increasingly important role in meeting the demand for raw materials in the coming decades. The AIE (International Energy Agency) estimates that by 2040 the recycled lithium used in batteries could be around 81,000 tons, an enormous increase compared to the 3,000 tons forecast for 2030. "

This partnership follows the one recently signed by Italvolt with AECOM, with the aim of optimizing production and increasing the resilience of lithium-ion batteries, minimizing waste in the life cycle of the project.

This is a machine translation from Italian language of a post published on Start Magazine at the URL https://www.startmag.it/smartcity/cosa-sappiamo-sulla-gigafactory-che-italvolt-vuole-in-piemonte/ on Tue, 23 Aug 2022 05:44:51 +0000.