What happens in the Stellantis factories in Italy

Numbers and comparisons from a report by the Fim-Cisl union on the Stellantis factories in Italy

Pomigliano did well, Cassino and Mirafiori did poorly. These are the trends for the Stellantis factories according to the framework disclosed by the Fim-Cisl union.

Here are numbers, comparisons and comments.

HOW IS THE PRODUCTION OF THE STELLANTIS GROUP GOING IN ITALY

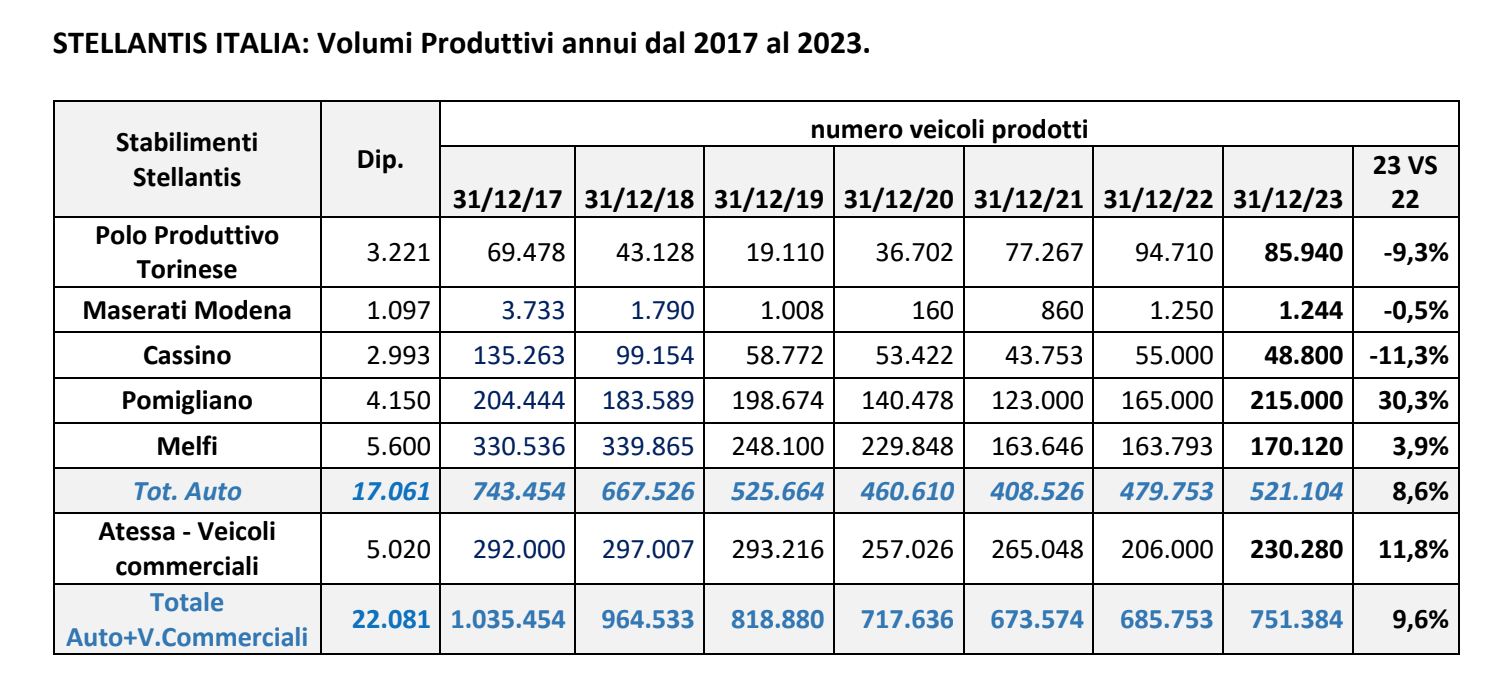

In 2023 in Italy the production of the Stellantis group grew for the second consecutive year, increasing by 9.6% to 751,384 units (they were 685,753 in 2022). This is what emerges from the traditional Fim-Cisl report – presented in Turin by the national secretary Ferdinando Uliano and the general secretary of the Turin Fim Rocco Cutrì – which highlights in detail how the production of cars marks a +8.6%, equal to 521,104 while that of commercial vehicles is increasing by +11.8%, with +24,280 units produced.

THE TREND OF THE LAST QUARTERS

After a difficult first quarter, the trend has been positive in the last three quarters, thanks to the reduction of production stops due to the lack of materials, which instead characterized 2022. However, despite the positive trend, the union recalls, the production of cars and commercial vehicles still remains below -8.2% of 2019, the pre-covid period, where it stood at a total of 818,880 units. For cars there is a substantial convergence (-0.9%), while for commercial vehicle production we are still at -12%.

COMPARISONS BETWEEN POMIGLIANO, CASSINO AND MIRAFIORI

The growth of 65,000 units was determined in particular by the production of the Pomigliano d'Arco and Atessa plants. “At 1 million vehicles (most commercial cars) 1/3 of the current volumes are missing, it is clear from the data how necessary it is to relaunch the production of Cassino and Mirafiori with new productions”, concludes the union.

HERE IS THE FULL REPORT FROM THE FIM-CISL:

STELLANTIS ITALY PRODUCTION SITUATION IN 2023

Production data in 2023 are improving compared to 2022, thus confirming the 2nd year of growth. In fact, there was growth of +9.6%. Specifically, in 2023, 751,384 units were produced, including cars and commercial vehicles, compared to 685,753 in 2022. The production of cars increased by +8.6%, equal to 521,104, while that of commercial vehicles increased by +11.8%. %, with +24,280 units produced, confirming the growth figure already recorded in the last three quarters, compared to a negative start to the year, in particular due to a reduction in production stops due to lack of materials, which instead characterized 2022.

The production of cars and commercial vehicles still remains below -8.2% of 2019, the pre-covid period, where it stood at a total of 818,880 units. For cars there is a substantial convergence (-0.9%), while for the production of commercial vehicles we are -12%.

The growth of 65,000 units was determined in particular by the production of the Pomigliano d'Arco and Atessa plants.

At 1 million vehicles (most commercial cars) 1/3 of the current volumes are missing, it is clear from the data how necessary it is to relaunch the production of Cassino and Mirafiori with new productions.

Situation in the final production plants

- Plant Production Center of Turin

Production volumes measured in 2023 reach 85,940 units, obtaining -9.3% compared to 2022, a negative figure after three years of production growth. The greatest weight in volumes continues to be determined by the production of the 500 bev which stops at 77,260 units, in fact at the same level as 2022 (77,500). Not a positive figure, given that the performance in the 1st half of 2023, driven by two-shift production, had given rise to hopes of an increase above 90,000 units. Unfortunately, the CIG days had an impact, which since October have also involved the 1200 workers on the 500e production line. Since the beginning of the year, there have been around 20 days of production shutdown plus 11 days of a long collective shutdown.

A market decline, particularly in the last quarter, worries us despite the company's reassurances which traces everything back to our country's delays in incentives for the purchase of sustainable cars and the lack of charging infrastructure.

The incentives communicated by MIMIT , first in the working group on the car table and subsequently made public, approved by Prime Ministerial Decree in January 2024, should give an important boost to the sale and production of the 500e. Furthermore, in January 2024, the commercial launch on the North American market was confirmed, for which a positive response in terms of volumes is expected.

On the Maserati line the production situation is much more critical. On the production front, 8,680 units were reached with the 5 models (GT, GC, Levante, Ghibli and QP), -49% compared to 2022. Adding another negative year to the Maseratis produced in the Turin hub, a very high level was reached critical, if you just consider that in 2017 production stood at almost 55,000 units. There were 99 days of production stops managed with the CIG which involved approximately 1780 workers in the first 9 months and 1052 in the remaining 3 months.

Towards the end of the 1st quarter of 2023, production of the Maserati Gran Turismo (GT) and Gran Cabrio (GC) began, reaching a total of 2790 units. Furthermore, the new full-electric Folgore versions of the GT and subsequently the GC will also be produced at the beginning of 2024.

Certainly the new GT and GC, even in their electric versions, may have better results in terms of volumes, but we believe there are no conditions to make up for the production stop of the Ghibli and Quattroporte and above all they cannot saturate, together with the Levante SUV, the production of the Maserati line.

The production launch of the new Quattroporte sedan model in its full-electric version is expected from 2025. We believe that there is no need to delay the production start-up, but it is necessary to accelerate and bring forward the timing of the production of the new sedan. It is important to understand Stellantis' strategy at Mirafiori for the future both on the models and on the volumes of Maserati production, given that the objective in the "Dare Foward 2030" plan is to increase three times the weight of new cars in the premium vehicle segments and luxury and we think that this should be done with a primary role for Mirafiori. Given the situation, we believe it is essential that in addition to the 500e and the Maserati models, another model on a full-electric platform with the potential for significant and non-niche volumes be assigned, in order to guarantee Mirafiori's production mission as a car assembly plant.

- Plant Maserati Modena

Production at the Modena plant is almost in line with the production data of the previous year. There are 1244 MC20s produced in 2023. In the last part of the year, a few CIG days had to be used in a very marginal way. Production of Maserati's MC20 super sports car should also maintain the same volumes for 2024. These volumes guarantee the saturation of the production capacity of the Modena plant which today develops on a daily shift.

Equally important is the investment in the 3rd quarter of the "Fuoriserie" project dedicated to luxury customization for all the Trident models which will also determine a positive impact on employment, thus consolidating and strengthening Maserati's presence in Modena.

At the beginning of 2025, the implementation of the Folgore full-electric platform on this car will allow further production continuity and safety. In the two Modena sites, in addition to the approximately 260 direct production sites, approximately 837 engineers are employed engaged in design and development activities which are at the service of all Stellantis entities. In the new structure of the R&D Centres, it will be fundamental that this important reality linked to research and design has its own continuity and development and does not undergo downsizing.

- Plant of Cassino

Production in 2023 was 48,800 units (-11.3%). It is the plant with the most significant decline compared to 2022. The current production is characterized by the volumes of the new Maserati Grecale with 17,242 units, equal to more than 1/3 of production and the remainder is represented by the two Alfa Romeo Stelvio and Giulia .

The increase in volumes of the Maserati Grecale, (+3,640 equal to + 27%), up compared to 2022, did not compensate for the decline seen on the two Alfa Romeos (-9,840 equal to – 24%).

The potential of the Cassino plant is greater than the current production, just think that in 2017 it was almost triple with 153,263, with a higher employment of 1,200 workers.

The plant is already producing the first full electric versions of the Maserati Grecale BEV, with the launch expected at the beginning of the year. The new Alfa Romeo Stelvio and Giulia models, which we recently saw already made in the Mirafiori Style centre, are developed on the Stla Large platform and will be produced at the Cassino site no earlier than 2025.

In recent months, the works to unify the painting and bodywork and prepare the assembly line for the new electrical productions were completed. Since the beginning of the year, there have been approximately 54 days of production downtime, which were necessary to carry out the work and to cope with a few days of production downtime due to lack of materials.

The assignment of the Stla large bev platform to the plant certainly represents a positive prospect for the future of the plant, now it is essential to quickly allocate other premium models, which will complement the production of the Maserati Grecale and the two new Alfas Romeo.

- Plant of Pomigliano

It is the plant that had the greatest growth during 2023, reaching 215,000 units, an increase of +30.3% . Since the restart of Panda production in 2011, Pomigliano has never achieved these productions.

The growth in volumes compared to 2022 is largely made up of the production increase of the new productions, the Alfa Romeo Tonale SUV and the Dodge Hornet SUV, which reached 82,300 units, in addition to the 132,700 Fiat Panda.

The two assembly lines produce on 12 weekly shifts, while 20 shifts are carried out in some areas of the plant such as bodywork, moulding, painting, plastic and logistics.

Starting from 1 January 2024, the use of the CDS for the Campania plant ends, a historic result for Fim-Cisl and the other unions who signed the agreements in 2011 with the start of production of the Panda . An even more significant result if we consider that workers from the former PCMA and the Nola logistics hub have also been included in the Pomigliano d'Arco perimeter in recent months.

Furthermore, to date, employment at the site has increased by over 1,150 workers, coming on temporary transfers from the Group's other sites, in particular from Melfi, Pratola Serra and Cassino.

The growth in production of the Tonale and the Dodge Hornet on the American market and the confirmation of the Fiat Panda, certainly until 2026 and in any case, as long as the legislation on endothermic production allows it, guarantee the production levels on the Neapolitan site for the next few years. After our requests, the Group also reiterated that the production of the "Panda will continue throughout its life cycle until the arrival of the new model cycle". These are important commitments that Stellantis will then have to assume with precise guarantees also at ministerial level in the development agreement for the auto sector.

- Plant of Melfi

The production data in 2023 is slightly growing +3.9% compared to the previous year. If we compare it to 2019, the loss is instead around 78,000 cars (-31.4%), the heaviest decline in the car factories.

The 170,120 cars produced are divided as follows: 29.8% 500x, 42.8% Jeep Renegade and 27.3% Jeep Compass. The slight improvement in 2022 is determined by the lower impact generated by production stops due to lack of material, which during 2023 were 73 days while in 2022 they were 104 days with a longer shift schedule.

The loss of approximately 1/3 of production compared to 2019 has led to negative repercussions in terms of employment, which have been addressed with various tools that are alternatives to layoffs, such as incentives for leaving on an exclusively voluntary basis (in the last year involved almost 1,450 workers, bringing employment to 5,600) and intra-group transfers for around 1,150 people.

From mid-May 2023 the shift schedule at the plant increased from 17 to 15 shifts.

However, the situation in Melfi is difficult and complex, especially in the transition phase towards the five new fully electric multi-brand models, on the Bev STLA Medium platform, which certainly represent a positive response in terms of future prospects for the Basilicata plant. At the meeting on 23 November last, at the Style Center in Turin, the national secretariats were able to view the new models and verify their potential.

The last part of 2023 was characterized by the entire phase necessary to accompany the transition of the Melfi plant towards the production of the five new models, to this end a new Solidarity Contract was stipulated expiring on 4 August 2024.

In October, with the confirmation of the fifth Jeep brand full electric model, which we requested as Fim-Cisl to give further guarantees for the future of the plant, we also verified the timetable for the start of the new productions and the connection with the current productions. Specifically, the production ramp-up of the first DS-branded full electric car will begin in the last quarter of 2024, followed in 2025 by two other cars, a Jeep and a DS, and in 2026 by the other two, an Opel-branded car and the Lancia Gamma. The Jeep Compass will also be produced in a latest generation hybrid version. The new battery assembly line will also be built and will start with the launch of the new models.

The release timetable of the current productions includes: the first to be released during 2024 will be the 500X and followed by the Jeep Renegade at the end of 2025.

For the related industries we are acting at an institutional level, both ministerial and regional, to have all the guarantees associated with avoiding negative impacts on employment. For us, the meetings held at the ministerial level in December and those scheduled from 22 January 2024 must represent the context in which to obtain those elements of guarantee that we do not have today. It is necessary for the Stellantis group to be committed to giving priority in supplies to the companies in the district, but at the same time, it is necessary to support the supplier companies in the process of modernization and transition towards new production. Furthermore, it is essential to act on the program agreement and on the instruments available in complex crisis areas to attract other new investments and to protect workers in the Melfi area.

- Plant of Atessa

Production of commercial vehicles in 2023 reached 230,280 units, with an increase of +11.8% compared to 2022, reversing the negative figure seen in the first months of the year. In 2021 and 2022 the situation of production stops due to lack of material had strongly affected production results. In 2023, production stops lasted a total of 15 days, largely concentrated in the 1st quarter. To date, the problem of materials seems almost completely resolved, this will lead to growth in terms of volumes also in 2024. In the Atessa (CH) plant, leader in light commercial vehicles, commercial vehicles from Fiat and Psa are also produced, as well as from Opel and Vauxall and those of Toyota should also start from 2024. The establishment of a specific area of the commercial vehicle business within Stellantis represents a clear sign of strengthening both in terms of investments and volumes, particularly for the Atessa plant.

The Abruzzo plant must continue to maintain leadership in commercial vehicles also in the Stellantis group, therefore to protect Italian production, we will continue to carefully monitor and verify the production balance within the Group. The daily production growth of the past quarter led to an increase in employment, currently temporary, of around 220 units between new hires of workers and transfers from other plants, the latter expected to amount to around 160.

Last September, 40 of the 180 staff leasing workers were stabilized with permanent Stellantis contracts. Our position remains that of trying to obtain other stabilizations in the future so as not to lose the professionalism in which we have invested, in particular in the context of continuous production growth.

THE INDUSTRIAL PLAN OF THE STELLANTIS GROUP

Summary of the “Dare Forward 2030” plan presented on March 1, 2022

The “Dare Forward 2030” plan targets zero carbon emissions by 2038. With a 50% reduction by 2030: 100% of sales in Europe and 50% in the United States will be electric vehicles battery-powered vehicles (BEV), with more than 75 models (45 in 2024), reaching approximately 5 million BEV vehicles. By 2025 the overall investment for electrification will be 30 billion, also including an increase in the production capacity of batteries from 140 GWh to 400 GWh, with three factories in Europe (including one in Termoli) and two in the USA. From 2022-2030 there will be a total of 100 launches of new models globally, out of no. 4 vehicle platforms (small, medium, large, frame) and n. 3 tech platforms.

The weight of new cars from the premium and luxury vehicle segments (Maserati, Alfa Romeo, Lancia and DS) will triple by 2030 (from 4% to 11%), revenues will increase fourfold and profitability fivefold. Leadership in the commercial vehicle market will be strengthened. Investments and expenses in R&D will be equal to 8% of revenues.

- Meetings to review the industrial plan of the Stellantis Group

The “Dare Forward 2030” Plan is adapted according to the context and changes that may influence strategies in the sector. This means that the plan must be constantly verified, through continuous discussion between the union and the company, including at institutional meetings. Meetings are held periodically at MiMIT, in the dedicated Stellantis table and in the sector table, as well as a series of verification meetings at local and national level. In particular, the meeting of the national observatory was held on November 23rd, as foreseen by the Specific Collective Labor Agreement (CCSL).

Our objective is that for each reality it is necessary to guarantee an industrial and employment perspective, taking on the objective of not closing factories but of transforming them technologically, with concrete and positive solutions within an ecological and digital transition that is affecting the automotive sector. Let's analyze the most relevant aspects that emerged in the latest meetings with the Stellantis Group and the institutions.

- Turin Manufacturing District : production hub for vehicles and components, where the company has confirmed its value as a design center for electrification and sustainability, the design heart of iconic Italian brands.

- Maserati GT and GC , production launch during 2023. Electric versions will also be produced from the beginning of 2024.

- The launch of the future Maserati luxury sedan E is expected in Mirafiori in 2025. We have been informed that the timing is being redefined to maximize the impact on the market. We reiterated that this should not constitute a delay in the production launch.

- The Fiat 500e built in Mirafiori will be exported to the United States from early 2024;

- The Joint venture with Punch Powertrain, called e-Transmissions , operational in February 2024, will host an advanced plant in Turin for the production and supply of innovative electrified transmissions for the new generation of hybrid and PHEV models. It will have an installed capacity of 600,000 electrified transmissions per year to support Stellantis' overall needs. Currently almost 100 people already work there (with a staff potential of 500 employees when fully operational). The assembly and testing activities of the production plants are currently underway;

- The first Circular Economy Hub , which aims to extend the life of components and vehicles, guaranteeing a longer life, was inaugurated on 23 November 2023, with around 200 workers, and will be fully operational in 2025 with around 500 units ;

- The Battery Technology Center was inaugurated in September 2023, where performance testing and validation of battery components for Stellantis electric vehicles will be carried out during the development and production phases;

- For the Central Bodies they reiterated their commitment to developing skills in research and innovation , linked in particular and not only to production in Italian factories, increasing collaboration with the Polytechnic. The research and development functions employ 4,500 workers in Italy (3,700 office workers and 500 workers) distributed as follows: Turin 3000, Modena 600, Pomigliano 500 and the remainder in the smaller centers of Balocco, Trento, Bari and Melfi.

- Investment on the Green Campus Mirafiori which will be completed in December 2025 will welcome 10,000 employees, including engineers, technicians and employees of the Central Authorities, at the same time we reiterated the need to strengthen and invest more in aspects relating to research and development, so that Turin is increasingly one of the four most important innovation centers in the mobility sector of the Stellantis group.

- Comau

- In the meeting on 30 October 2023, the company management confirmed the spin-off already announced some time ago, without communicating any details in terms of timing and methods. Therefore, many elements of uncertainty remain. We have expressed our concern that this important reality in the robotics, industrial automation and e-mobility sector, which employs around 700 people in Italy and over 3,500 worldwide, could be sold to third-party companies with the obvious risk of impoverishing further the heritage of research and development in our country in such a technologically advanced field.

We reiterated the request to be promptly updated and involved in any developments in the situation. In the meantime, at government level we have asked the government to also consider the possibility of activating the golden power, to then activate all the guarantee elements to protect industrial and employment assets.

- Teksid

- There are approximately 1,000 workers present in the Carmagnola foundry. The production is all dedicated to components, cylinder head and crankcase, relating to internal combustion engines and therefore destined for a downsizing as 2030 approaches. In the last meeting the company reiterated that it remains the Group's aluminum hub of excellence with the objective of compensating for production being reduced, with new production of lighter components required by the ongoing transformations of electric cars. For this reason he believes that there are no problems in the short term, in fact the battery boxes have been put into production and the project to build the metal boxes to contain the hardware systems and oil sumps will soon be launched. For us, continuous monitoring and verification of the real employment impacts is essential and above all to have certain answers regarding future prospects.

- Verrone

- From 2024, the sole transmission supplier of commercial vehicles produced in Atessa and Cliwice

- Modena

- Production and development of the various versions of the Maserati MC20, with electrification expected in 2025. In the 3rd quarter of 2024, an investment will be made in the project called "Fuoriserie", a new paint shop, for the customization of all Maserati cars.

- Cassino

- Production of the Folgore electric platform on the Maserati Grecale has started. With the award of the Stla Large platform it will become the leading plant to produce the next generation of vehicles for premium and luxury brands such as Alfa Romeo and Maserati. At the Style Center we saw the future Alfa Romeo Stelvio and Giulia developed on the new platform where they will also be produced in electric versions from 2025.

- Pomigliano d'Arco

- The Alfa Romeo Tonale and Hornet Dodge have been in production since the 2nd half of 2022. If regulatory developments allow it, Stellantis intends to extend the life cycle of the Panda, even beyond 2026 and therefore support the plant until the arrival of the new model cycle.

- Melfi:

- From the last quarter of 2024 to 2026, the 5 new multi-brand models will be launched on the Stla medium platform, the battery line and renewal of the hybrid and plug-in engines of the models currently in production.

- Atessa

- 85% of Atessa's production is exported. The Atessa plant will be one of the main global production points for new electrified commercial vehicles for the Citroën, FIAT Professional, Opel, Peugeot and Vauxhall brands, as part of the strategic Pro One offensive for Stellantis' commercial vehicle division. The agreement with Toyota on commercial vehicles confirmed will have positive impacts on Atessa's commercial vehicles starting from 2024.

- Center of Ferrara

- having reiterated the commitment made in the union agreements on marine and industrial engine BUs, for these productions, the plant has achieved complete functional autonomy. It is necessary to continue to strengthen the reindustrialization plan of the area as well as verifying the necessary guarantees for the future should the possibility of transfer arise, which is increasingly probable even if not officially confirmed.

- Termoli

- The start of the third European Gigafactory and related production start-up in 2026 has been confirmed. Automotive Cells Company ACC, the joint venture between Stellantis, Saft/Total Energy and Mercedes-Benz, currently employs just over 20 people. Negotiations are underway at ministerial level where a specific table has been set up with MiMit, Ministry of Labour, ACC, Stellantis, local institutions and trade unions to build the conditions necessary to provide all the guarantees in the transition phase, on an industrial level and employment, coverage of social safety nets, professional training as well as all aspects relating to contractual protection, both regulatory and economic.

- Pratola Serra

- From the end of 2024 it will be the only plant to supply B2.2 Euro 7 diesel engines for all the Group's commercial vehicles.

In the various meetings we had with companies and institutions, both national and local, we asked that in addition to the specific requests on the allocation of new production in the factories and the volumes of future production, it is necessary to have guarantees on the research and development functions assigned to our country and on the supplies relating to the related industries and components of the Italian factories.

The permanent table for Automotive Development was established on 6 December 2023

After four months of delay the car table finally started. It is now essential that this system table achieves the objective of building a development agreement with Stellantis and all the players in the Italian automotive sector for the increase in production levels in the Italian factories, the consolidation of the engineering and research centers, greater investments in innovative models, the retraining of workers' skills and support for the reconversion of the components supply chain. To this end, the five working groups on the Market (incentives, future developments), on Competitiveness (efficiency, energy, etc.), on Components, on Work and skills and, finally, on R&D are already functioning and reconvened from 22 January 2024. and engineering centers. The meeting was attended by MIMIT, the Ministry of Labour, Stellantis, the Regions, Anfia and the trade union organizations FIM-CISL, FIOM-CGIL, UILM-UIL, FISMIC and UGLM.

In the settlement meeting we underlined the importance of finally having convened a sector table with the involvement of all the players in the automotive supply chain. To address the ongoing transitions in the automotive sector, it is important to target the available resources precisely with investments. Of course we all agree on the objectives of increasing production, but we must establish the implementation times, knowing that the million vehicles (cars + commercial vehicles) means increasing current production by a third. If the one million target is just for cars this means doubling production.

As regards each production site, the discussion for us will have to concern not so much the Italian nature of the Stellantis brands, but which and how many new models will be produced in our country. Today the group is a multinational that already produces brands such as Jeep, Dodge and in the future also DS and Opel in Italy. If on some plants we have certain production missions such as that of Melfi, on other sites there is the need to do an in-depth analysis and define new models and departure times. We need a discussion on the saturation of the factories, on the models that will be produced in the future and on how volumes and investments in R&D will increase.

As regards the remaining 6 billion (compared to the 8 billion that constituted the car fund), they must be used not only for purchase incentives, but to invest in supply, i.e. in the industry and the component supply chain, which otherwise would risk a strong downsizing.

It is necessary to concretely create the conditions for development and growth of production and employment volumes for the Stellantis factories in Italy and for the components sector. We must use resources for reindustrialisation, which are essential to avoid the negative impact of over 75,000 workers in the automotive sector following the change in engines. There are many crisis situations in the auto sector that are taking a heavy toll: Marelli of Crevalcore, Bosch of Bari, Denso of San Salvo, Lear, Te Connetivity, the companies that produce exhaust systems. We need to shorten the supply chain, bringing to Italy the production of all the components that will represent the car of the future, from semiconductors, from batteries, to the components necessary for electric motorization, for autonomous driving, for digitalization and connectivity. Without an industrial transition plan that can be activated immediately, the risk of dismissal and industrial desertification becomes a certainty.

This is a machine translation from Italian language of a post published on Start Magazine at the URL https://www.startmag.it/smartcity/cosa-succede-negli-stabilimenti-di-stellantis-in-italia/ on Fri, 05 Jan 2024 14:54:29 +0000.